Con il comunicato stampa di seguito allegato, Intel Corporation ha annunciato una innovazione tecnologica destinata ad inaugurare una nuova era nel mondo dell'elettronica: il transistor 3D, denominato Tri-Gate. Più in dettaglio, la notizia non risiede tanto nella introduzione del dispositivo in se, dal momento che il suo sviluppo è stato completato dalla stessa Intel nel 2002, ma nel passaggio di questo in produzione.

Intel, infatti, si è detta pronta a supportare la produzione in volumi dei Tri-Gate, ottenuti con un processo di fabbricazione a 22nm: essi saranno alla base dei processori "Ivy Bridge", con i quali Intel rinnoverà la linea di cpu Core, attualmente basata sui chip "Sandy Bridge"; successivamente, la nuova tecnologia sarà estesa anche al mondo Atom. L'avvio della produzione degli "Ivy Bridge" avrà luogo alla fine del 2011; il lancio commerciale degli stessi si concretizzerà invece soltanto nel 2012.

I transistor a tre dimensioni Tri-Gate rappresentano una fondamentale evoluzione delle attuali soluzioni planari a due dimensioni, che da oltre 50 anni sono alla base di qualsiasi sistema elettronico, indipendentemente dall'ambito a cui questo è indirizzato, e che a loro volta hanno innescato una rivoluzione sostituendo le valvole; i Tri-Gate, infatti, hanno un punto di polarizzazione più basso di qualsiasi transistor attualmente sul mercato, pur offrendo prestazioni superiori.

In accordo alla stessa Intel, i transistor Tri-Gate a bassa polarizzazione offrono performance superiori del 37% rispetto ai transistor planari a 32nm prodotti dallo stesso maker (questa feature fa capire la naturale predisposizione per l'impiego dei Tri-Gate nell'ambito mobile, ndr); da un altro punto di vista, non meno significativo, i nuovi transistor 3D offrono le stesse prestazioni di quelli 2D, ma consumano la metà.

[Immagine ad alta risoluzione]

Intel Corporation today announced a significant breakthrough in the evolution of the transistor, the microscopic building block of modern electronics. For the first time since the invention of silicon transistors over 50 years ago, transistors using a three-dimensional structure will be put into high-volume manufacturing. Intel will introduce a revolutionary 3-D transistor design called Tri-Gate, first disclosed by Intel in 2002, into high-volume manufacturing at the 22-nanometer (nm) node in an Intel chip codenamed "Ivy Bridge." A nanometer is one-billionth of a meter.

The three-dimensional Tri-Gate transistors represent a fundamental departure from the two-dimensional planar transistor structure that has powered not only all computers, mobile phones and consumer electronics to-date, but also the electronic controls within cars, spacecraft, household appliances, medical devices and virtually thousands of other everyday devices for decades.

"Intel's scientists and engineers have once again reinvented the transistor, this time utilizing the third dimension," said Intel President and CEO Paul Otellini. "Amazing, world-shaping devices will be created from this capability as we advance Moore's Law into new realms."

Scientists have long recognized the benefits of a 3-D structure for sustaining the pace of Moore's Law as device dimensions become so small that physical laws become barriers to advancement. The key to today's breakthrough is Intel's ability to deploy its novel 3-D Tri-Gate transistor design into high-volume manufacturing, ushering in the next era of Moore's Law and opening the door to a new generation of innovations across a broad spectrum of devices.

Moore's Law is a forecast for the pace of silicon technology development that states that roughly every 2 years transistor density will double, while increasing functionality and performance and decreasing costs. It has become the basic business model for the semiconductor industry for more than 40 years.

Unprecedented Power Savings and Performance Gains

Intel's 3-D Tri-Gate transistors enable chips to operate at lower voltage with lower leakage, providing an unprecedented combination of improved performance and energy efficiency compared to previous state-of-the-art transistors. The capabilities give chip designers the flexibility to choose transistors targeted for low power or high performance, depending on the application.

The 22nm 3-D Tri-Gate transistors provide up to 37 percent performance increase at low voltage versus Intel's 32nm planar transistors. This incredible gain means that they are ideal for use in small handheld devices, which operate using less energy to "switch" back and forth. Alternatively, the new transistors consume less than half the power when at the same performance as 2-D planar transistors on 32nm chips.

"The performance gains and power savings of Intel's unique 3-D Tri-Gate transistors are like nothing we've seen before," said Mark Bohr, Intel Senior Fellow. "This milestone is going further than simply keeping up with Moore's Law. The low-voltage and low-power benefits far exceed what we typically see from one process generation to the next. It will give product designers the flexibility to make current devices smarter and wholly new ones possible. We believe this breakthrough will extend Intel's lead even further over the rest of the semiconductor industry."

Continuing the Pace of Innovation – Moore's Law

Transistors continue to get smaller, cheaper and more energy efficient in accordance with Moore's Law – named for Intel co-founder Gordon Moore. Because of this, Intel has been able to innovate and integrate, adding more features and computing cores to each chip, increasing performance, and decreasing manufacturing cost per transistor.

Sustaining the progress of Moore's Law becomes even more complex with the 22nm generation. Anticipating this, Intel research scientists in 2002 invented what they called a Tri-Gate transistor, named for the three sides of the gate. Today's announcement follows further years of development in Intel's highly coordinated research-development-manufacturing pipeline, and marks the implementation of this work for high-volume manufacturing.

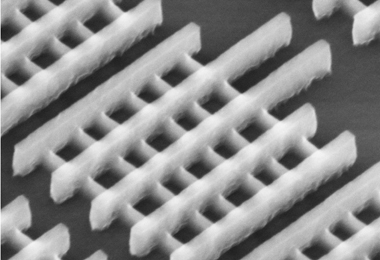

The 3-D Tri-Gate transistors are a reinvention of the transistor. The traditional "flat" two-dimensional planar gate is replaced with an incredibly thin three-dimensional silicon fin that rises up vertically from the silicon substrate. Control of current is accomplished by implementing a gate on each of the three sides of the fin – two on each side and one across the top -- rather than just one on top, as is the case with the 2-D planar transistor. The additional control enables as much transistor current flowing as possible when the transistor is in the "on" state (for performance), and as close to zero as possible when it is in the "off" state (to minimize power), and enables the transistor to switch very quickly between the two states (again, for performance).

Just as skyscrapers let urban planners optimize available space by building upward, Intel's 3-D Tri-Gate transistor structure provides a way to manage density. Since these fins are vertical in nature, transistors can be packed closer together, a critical component to the technological and economic benefits of Moore's Law. For future generations, designers also have the ability to continue growing the height of the fins to get even more performance and energy-efficiency gains.

"For years we have seen limits to how small transistors can get," said Moore. "This change in the basic structure is a truly revolutionary approach, and one that should allow Moore's Law, and the historic pace of innovation, to continue."

World's First Demonstration of 22nm 3-D Tri-Gate Transistors

The 3-D Tri-Gate transistor will be implemented in the company's upcoming manufacturing process, called the 22nm node, in reference to the size of individual transistor features. More than 6 million 22nm Tri-Gate transistors could fit in the period at the end of this sentence.

Today, Intel demonstrated the world's first 22nm microprocessor, codenamed "Ivy Bridge," working in a laptop, server and desktop computer. Ivy Bridge-based Intel Core family processors will be the first high-volume chips to use 3-D Tri-Gate transistors. Ivy Bridge is slated for high-volume production readiness by the end of this year.

This silicon technology breakthrough will also aid in the delivery of more highly integrated Intel Atom processor-based products that scale the performance, functionality and software compatibility of Intel architecture while meeting the overall power, cost and size requirements for a range of market segment needs.

News Source: Intel Press Release

Links

|